Industrial furnace equipment property management services refer to the industrial furnace equipment used by the owner. Our company is responsible for the care, maintenance, and repair of the equipment, as well as the overhaul, relocation, and transformation of the equipment after many years of use. Our company has a professional technical team, mature management experience, and advanced technical concepts. Based on the existing conditions, we use refined management methods to enable owners to reduce operating expenses, avoid spare parts financial risks, deeply tap energy-saving potential, and achieve energy saving and reduction. discharge and share energy-saving results.

Advantages of Industrial Furnace Property Management Services

l Reduce the management burden of owners and enjoy high-quality and efficient services

After adopting the industrial furnace property management service, our company's professional management team will promptly propose optimization and transformation plans for the shortcomings and deficiencies that occur during the operation of industrial furnace equipment, and gradually plan the operation and management of industrial furnaces to reflect the level of refined equipment management.

l Improve owners’ liquidity

Our company will stock the wearing parts of each piece of equipment, so owners do not need to keep spare parts inventory, which reduces financial pressure and improves the owner's capital liquidity.

l Achieve energy conservation and emission reduction

Our company's professional management team proposes targeted energy-saving and emission-reduction plans based on different usage needs to maximize energy savings and reduce emissions.

Main maintenance items:

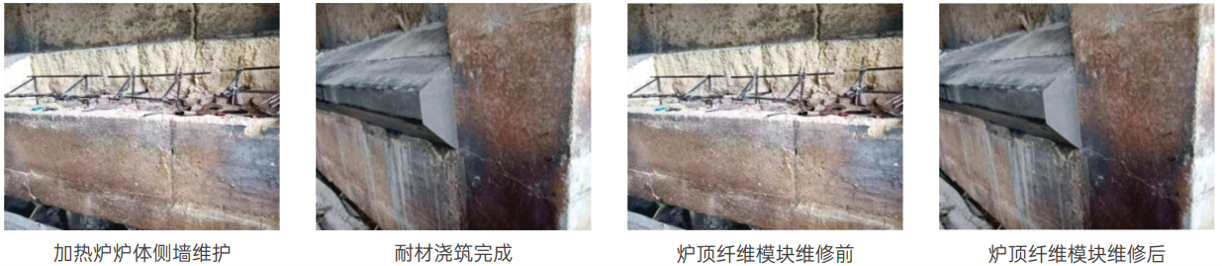

1. Maintenance of furnace steel structure

1. Rust removal and painting of furnace steel structure.

In view of the fact that owners generally use furnaces that have been built for a long time, the steel structure of the furnace body will undergo high-temperature corrosion to varying degrees, causing rust on the surface of the steel structure. We generally use manual or mechanical methods to perform rust treatment, and finally achieve the original appearance by spraying paint. Effect.

2. All bolts should be strengthened regularly and replaced if damaged.

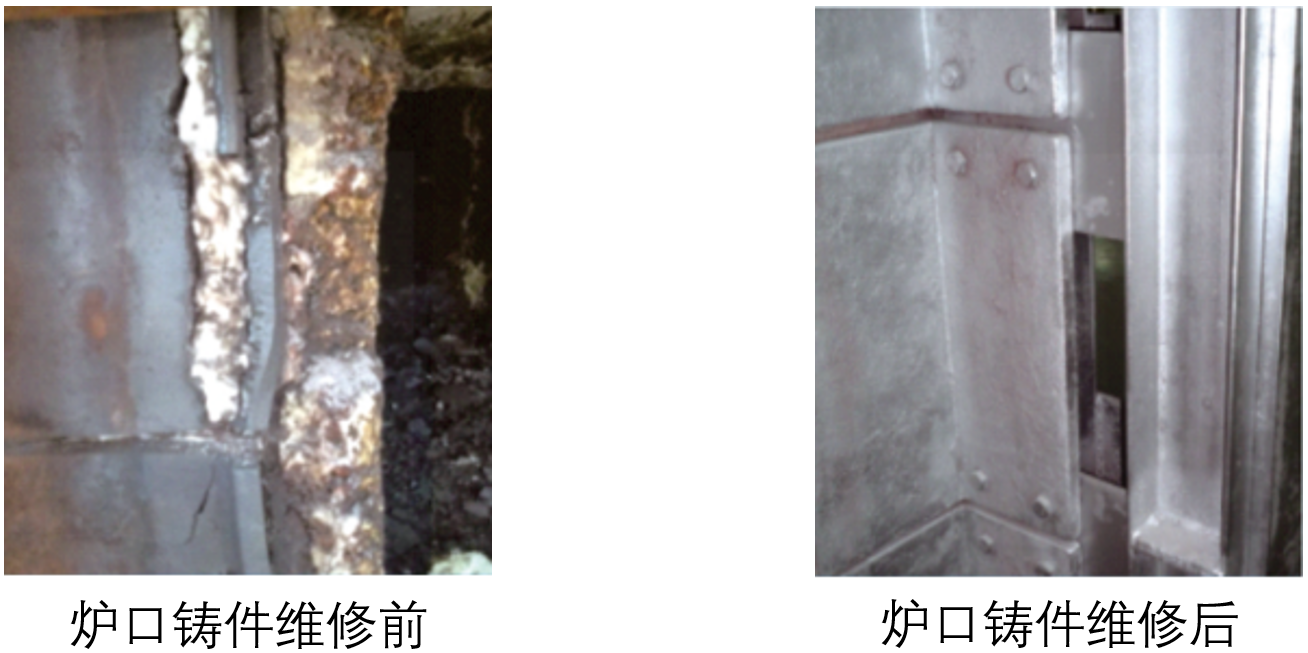

3. Inspection, repair and replacement of burnt damage of furnace door and furnace mouth castings.

2. Maintenance of trolley and driving mechanism

1. Maintenance of the trolley driving mechanism: maintenance of blunt teeth, regular replacement of gearbox gear oil; check the wear of the chain.

2. Maintenance of trolley frame castings: Check the burning condition of the trolley frame castings, and replace them if they are severely burned.

3. Maintenance and replacement of trolley refractory materials: The trolley furnace lining that supports the workpiece generally adopts a composite structure. The lower part is made of lightweight clay bricks and insulation bricks to form a thermal insulation layer, and the upper part is made of large heavy-duty linings with high thermal shock resistance and wear resistance. The high-quality bricks are built in a square grid shape, and the heavy-quality bricks support the weight of the workpiece and have high strength and good impact resistance; the square grid is made of lightweight clay bricks, shaped bricks, etc. to form a composite furnace lining, and arches are left along the longitudinal and transverse directions of the trolley. Expansion joints to prevent refractory bricks from swelling. Heavy refractory clay bricks are used on both sides of the trolley furnace and other parts that are prone to collision to reduce collision damage and ensure durability and energy saving.

3. Maintenance of furnace door lifting mechanism

1. Determine whether the lifting wire rope needs to be replaced.

2. Check the gear oil of the electric hoist and replace the gear oil regularly.

3. Perform key maintenance on the lifting mechanism braking system.

4. Maintenance of furnace door slides and wheel shafts.

4. Maintenance of pipeline valves

1. The smoke exhaust pipe valves should be cleaned and replaced regularly.

2. The combustion air pipe valves should be cleaned and replaced regularly.

3. The gas management manual valve should be cleaned and replaced regularly.

4. Electric valves in gas pipelines should be regularly tested for leaks and tightness inspections.

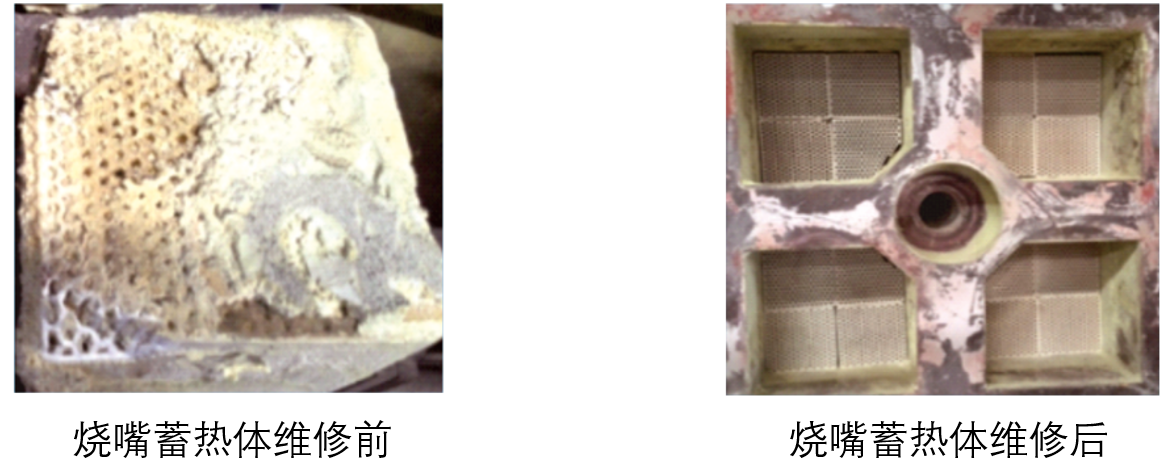

5. Maintenance of combustion system

1. Regularly replace the heat storage body

2. Regularly observe the combustion condition of the burner: if there is black smoke at the end of the flame, it indicates insufficient combustion, and necessary air-fuel ratio adjustments should be made. If the flame appears unstable or divergent, the burner brick needs to be inspected.

3, Check gas inlet pressure regularly

4, Regularly check the outlet pressure of the pressure reducing valve

5, regular measurements Combustion fan wind pressure

6, regularly measure the differential pressure of the exhaust fan

7, Regularly check the gas inlet filter

8 regularly remove carbon deposits on the flame sensor

9, Regularly check the carbon deposits on the ignition electrode

10, regular inspection and operation of gas or combustion air regulating valve

11, Regularly check the action of the reversing valve

12. Regularly check the leakage of gas pipelines, and if any problems are found, they need to be dealt with immediately

13, check whether the burner brick is cracked or falling off, and quickly repair or replace if any problems are found

14, Maintenance and replacement of wearing parts such as , solenoid valves, pressure gauges, flow meters, indicator lights, buttons, etc.

6. Maintenance of control system

1. Check the temperature inside the control cabinet: If the temperature exceeds 40, you need to check the side wall of the cabinet. Is the axial fan working properly? If not, it is recommended to install a fan. If you have a cabinet air conditioner, you also need to check regularly whether the air conditioner is working properly.

2, check whether the PLC indicator light in the control cabinet is working normally.

3. Check whether the grounding of the control cabinet is intact.

4, check whether the main circuit control components of the power cabinet are in normal working condition.

5, check whether PLC communication is normal.

6. Check whether various transmission motors are in normal working current state. If the rated working current of the motor is exceeded, it means there is a problem with the mechanical transmission and the mechanical equipment needs to be checked.

7. Regularly test the operating current of high-power motors and make corresponding records.

8. Regularly lubricate the end cover bearings of high-power motors.

7. Maintenance of furnace refractory materials

For type-type furnaces, damaged parts should be dealt with in a timely manner, maintenance plans should be made in advance, and owners should carry out technical modifications or replacements during mid-term repair or overhaul. For refractory materials such as fiber modules and insulation bricks, regular maintenance is also required.