From December 12 to 15, 2023, Sheng Yonggang, Chairman of Hehe Energy, accompanied Yang Kai, Deputy Secretary-General of the Welded Pipe Branch of the China Metal Materials Circulation Association, Steel Pipe Standard Promotion Committee, and Wu Yingchuan, Director of the Information Department, to Tianjin and Tangshan. , visited member companies of the Welded Pipe Branch of China Finance Association to conduct research on the steel pipe industry.

Hehe Energy attaches great importance to its own technological innovation and devotes itself to the research and development of cutting-edge technologies in the industry. It now has a number of invention patents and utility model patents. With itself as a supporting unit, it has jointly built metallurgical gas industrial furnaces with Beijing University of Science and Technology and other units. Industrial Technology Research Institute conducts multiple projects simultaneously to improve product performance and quality. Among them, Hehe Energy's original technology product - HHDX ultra-low nitrogen burner for galvanizing furnaces, can achieve NOx emissions of less than 30 mg/m³. It uses a unique hierarchical structure to make the natural gas burn more fully and reduce the waiting time of the zinc pot, thereby achieving the effect of energy saving and emission reduction at the source. The picture below shows the special HHDX ultra-low nitrogen burner for galvanizing furnace.

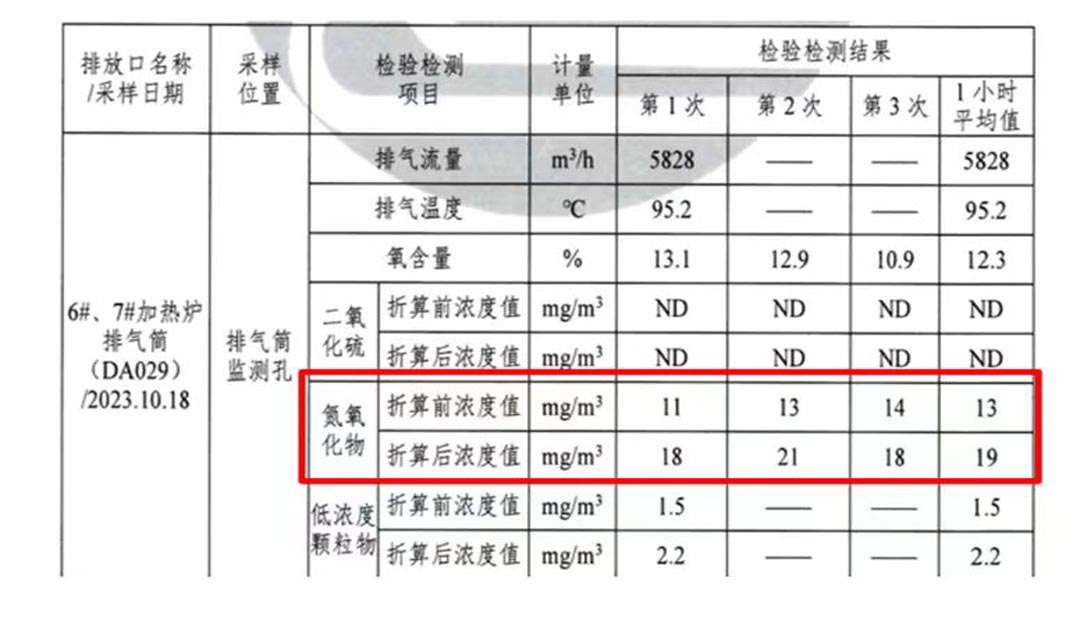

At present, this burner has been used in 8 galvanizing production lines of Tangshan Jinghua Pipe Manufacturing Co., Ltd., and the on-site nitrogen oxide emission after third-party inspection is 19mg/m³; according to Jinghua statistics, the average ton gas consumption is 11.3m³/t. Compared with before the transformation, about 1.5m³ of natural gas is saved per ton. In addition, combined with the actual application effect of the burner, the energy-saving low-nitrogen burner was once again transformed for the Jinghua square tube galvanizing production line. A consensus has been reached and a transformation contract has been signed. The picture below shows a third-party nitrogen oxide test report.

On December 12, we visited Tianjin member companies of the Welded Pipe Branch of China Finance Association. Ma Shaodan, deputy general manager of Tianjin Baolai Steel (Group) Co., Ltd., Ren Jiayi, deputy general manager of Tianjin Tianyingtai Steel Pipe Co., Ltd., Zhou Jie, deputy general manager of Tianjin Lianzhong Steel Pipe Co., Ltd., and deputy general manager of Tianjin Baosheng Steel Trading Co., Ltd. Manager Liu Jinhua attended the exchange event. The picture below shows a group photo taken at the scene.

On December 13, they visited Tianjin Youfa Dezhong Steel Pipe Co., Ltd. and Tangshan Zhengyuan Pipe Industry Co., Ltd. respectively. Li Bingshang, deputy general manager of Tianjin Youfa Dezhong, and Li Maohua, general manager of Tangshan Zhengyuan, attended the exchange activities. The picture below shows the communication scene of Tianjin Youfa Dezhong.

On the morning of December 14th, I visited Tangshan Youfa New Construction Equipment Co., Ltd., Deputy General Manager Yu Xiuchen and Assistant General Manager Ma Chengbao attended the exchange meeting and accompanied them to visit the production workshop. The picture below shows the on-site visit and group photo.

On the afternoon of December 14, we visited Tangshan Jinghua Pipe Manufacturing Co., Ltd. to observe the production work of the galvanizing furnace combustion system modified by Hehe Energy. Liao Canjun, deputy general manager of Jinghua, attended the exchange meeting and accompanied him to visit the production line. The picture below shows a group photo taken at the scene.

During these four days of visits and exchanges, Chairman Hehe Energy responded to the association’s strategic goals of “green development, consumption reduction and emission reduction” and demonstrated to the association secretary-general and association member companies the current stage of Hehe Energy’s “double carbon” Under the goal, excellent technical results have been achieved. The member companies of the association recognized the technical achievements displayed by Hehe Energy and affirmed Hehe Energy's contribution to the green development of the industry. Secretary-General Yang Kai affirmed the results achieved by Hehe Energy at this stage, and said that in order to promote "carbon peaking and carbon neutrality" and achieve "green development, consumption reduction and emission reduction", enterprises should vigorously develop new technologies and export new technologies to the outside world. Promote technological achievements and help enterprises achieve green and sustainable development with "saving costs and low pollution".